Hydrogen continues to gain popularity, and its use as an energy vector raises a lot of hope, particularly in the fight against greenhouse gas emissions, especially for the industry, to the point that France gives it a central role in its energy transition [1]. However, significant obstacles remain to be overcome, as hydrogen production is complex and primarily relies on carbon-based processes, requiring polluting resources. Although some sustainable alternatives exist, such as water electrolysis, they remain both too costly and require renewable electricity production far beyond existing capacities. This is the crux of the problem: hydrogen must be decarbonized, competitive, and rely on large-scale decarbonized energy production to be considered a viable energy vector for the future.

A European scientific consortium, coordinated by ESPCI Paris - PSL, has addressed this issue and proposes new perspectives for hydrogen production using an innovative and renewable process. The project Metal Organic Frameworks for hydrogen production by photocatalytic overall water splitting (MOF2H2) brings together 8 partners [2] from 4 different countries.

Let’s briefly return to hydrogen, or rather to dihydrogen (H2), its gaseous form composed of two chemically bonded hydrogen atoms, because it is the latter that is used as an energy vector and not hydrogen as such. Whether through methane reforming, biomass gasification, or electrolysis, there are many methods for producing dihydrogen. The MOF2H2 project aims for the production of dihydrogen by water photolysis, which means dissociation of water under the effect of radiation, such as solar radiation: the action of light energy chemically dissociates the oxygen (O2) from the dihydrogen (H2) present and combined in the water molecules (H2O). This method is still uncommon, partly because of the amount of energy required for the selective splitting of water and the use of noble metals, sometimes necessitating the addition of a chemical additive, making this process currently uncompetitive.

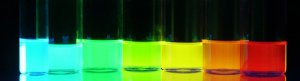

However, the contribution of a recent discovery—patented by ESPCI Paris - PSL and the Polytechnic University of Valencia—could lead to a breakthrough in this field. By using metal-organic frameworks (MOFs) as photocatalysts for the chemical reaction of water splitting, the process achieves high levels of solar energy conversion into dihydrogen while avoiding the use of noble metals, making the photolysis approach very attractive.

MOFs are crystalline solids with a highly ordered structure and high porosity, consisting of assemblies of metal ions and organic ligands. These materials can achieve very high specific surface areas (sometimes several thousand m²/g), combined with great structural and chemical versatility, making them ideal catalysts. Combined with non-noble metal co-catalysts, these MOFs could optimize the process and convert up to 5% of the captured solar energy into dihydrogen, a record that brings us closer to the criteria necessary for industrial hydrogen production by photocatalysis!

The idea for this project was born following a discovery made at the IMAP laboratory [3], directed by Christian Serre. An ESPCI graduate, a recognized specialist in porous solids, and recently appointed academician, Christian Serre is the scientific coordinator of the MOF2H2 project. ESPCI Paris – PSL also holds a special place in this project as it is the coordinator, animates, coordinates the consortium, and is the project’s spokesperson to European institutions. It is notably at the school where MOFs are selected, synthesized, and optimized. The MOF2H2 project team can also count on a second school graduate, Camille Michel. Camille is a consultant for Euroquality, she ensures the communication and visibility of the project and assists ESPCI Paris – PSL in its exchanges with European institutions.

The MOF2H2 project was launched in November 2022 with the objective of confirming the interest of MOFs as photocatalysts for hydrogen production and subsequently convincing that this type of production is likely to be scaled up industrially. While this production method alone will only complement hydrogen production by electrolysis, it will contribute to the reduction of greenhouse gas emissions in many sectors of activity, helping Europe to achieve the targets set by the Paris Agreement. MOF2H2 also illustrates high-level scientific collaboration between several European partners on a key and promising theme.

![]()

Disclaimer : This project is founded by the European Union under the Grant Agreement #101084131. Views and opinions expressed are however those of the author(s) only and do not necessarily reflect those of the European Union or CINEA. Neither the European Union nor CINEA can be held responsible for them.

–