Reflectometry

Reflectometry is a technique which relies on the local change of reflection

coefficient in a heated sample. In such, requirements on sample surface

finish place conditions on what pretreatment may be required. The technique

is more complex than direct IR radiometry in that in addition to a modulated

source it requires a probe beam, which is reflected off of the sample

surface. The relative change of the sample reflectance due to the

temperature change in the typical linear case is given by

Reflectometry is a technique which relies on the local change of reflection

coefficient in a heated sample. In such, requirements on sample surface

finish place conditions on what pretreatment may be required. The technique

is more complex than direct IR radiometry in that in addition to a modulated

source it requires a probe beam, which is reflected off of the sample

surface. The relative change of the sample reflectance due to the

temperature change in the typical linear case is given by

Delta R/R=(1/R)(dR/dT)Delta T

The temperature coefficient dR/dT depends on probe wavelength and

the sample material. By comparing with known values, and measuring

Delta R/R, typically on the order of 10-6, we can deduce Delta T

, the temperature variation, which is on the order of

10-2. This carries information about the local temperature parameters

of the sample such as the thermal diffusivity D. This heated interaction

volume can vary with pulsation variation, and is shown right.

With this method we may draw a temperature map on a micronic scale, and so

analyze complicated samples such as laser diode facets and electronic

devices. We may also measure thermal diffusivity on a microscopic scale in

granulated samples such as AlN and Al2O3 or thermal

barriers in Fe sintered samples.

Our experimental setup is built up under an optical microscope, with a

dichroic mirror inserted to direct the incoming pump laser (typically an

Ar+) down onto the sample, which is mounted on a computerized translation

stage. The probe beam, typically a visible diode laser, traverses the

microscope optical chain, and is reflected back through the microscope, and

directed by a beam splitter onto a photodiode. In order to optimize thermal

map resolution, modulation frequencies upto a few MHz are used. A diagram of

the experimental setup is shown on the left.

Our experimental setup is built up under an optical microscope, with a

dichroic mirror inserted to direct the incoming pump laser (typically an

Ar+) down onto the sample, which is mounted on a computerized translation

stage. The probe beam, typically a visible diode laser, traverses the

microscope optical chain, and is reflected back through the microscope, and

directed by a beam splitter onto a photodiode. In order to optimize thermal

map resolution, modulation frequencies upto a few MHz are used. A diagram of

the experimental setup is shown on the left.

Thermal properties may be mapped out by carrying out the measurement over a

grid of points on the sample surface. As the optical characteristics of the

sample are important for the reflection of the probe beam, the geometry may

be changed slightly to provide scanning of the pump beam. In this way, the

sample surface need be prepared only at the probe location.

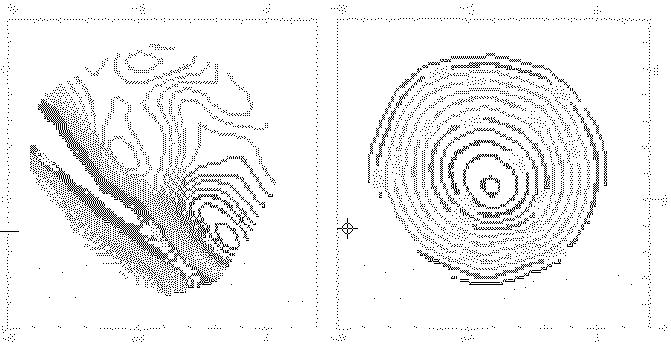

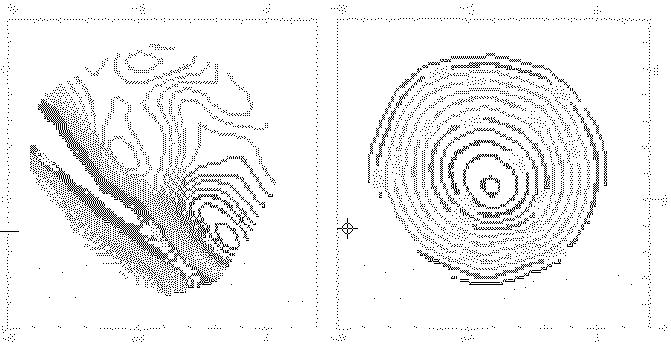

A measurement on

a gold sample with a scratch is shown below. On the left, the

scratch is clearly visible in the the reflectance values. On the right, the

phase pattern, related to the spherical shape of the heating spot is shown

as a contour plot, with equally spaced circles corresponding to equal phase

increments. The graduations, visible on the edges of the plots, are in

micrometers.

Furthermore, nonlinear effects such as temperature dependance of the thermal

diffusivity or additional effects such as free photocreated carrier

diffusion may be studied by including their influence in the reflectance

equation. For instance, should we wish to study the influence of carriers

(electron or hole) in silicon samples, we include a term for the change of

carrier density vis:

Delta R/R=(1/R)(dR/dT)Delta T+(1/R)(dR/dN)Delta N

The carrier density, inferred from the carrier diffusion equation, which can

be solved in the same way as the thermal diffusion equation, acts as a

source term in the heat diffusion equation. Typical values of the

contributions are dR/dT=10-4 and dR/dN=10-7

and we note that a 180° phase difference is to be expected in the

contribution of these two terms. With this method, the level of implantation

has been determined in different samples, and electronic

diffusivity coefficients determined unambiguously.

Return to the top/

Retour à la page principale

Our experimental setup is built up under an optical microscope, with a

dichroic mirror inserted to direct the incoming pump laser (typically an

Ar+) down onto the sample, which is mounted on a computerized translation

stage. The probe beam, typically a visible diode laser, traverses the

microscope optical chain, and is reflected back through the microscope, and

directed by a beam splitter onto a photodiode. In order to optimize thermal

map resolution, modulation frequencies upto a few MHz are used. A diagram of

the experimental setup is shown on the left.

Our experimental setup is built up under an optical microscope, with a

dichroic mirror inserted to direct the incoming pump laser (typically an

Ar+) down onto the sample, which is mounted on a computerized translation

stage. The probe beam, typically a visible diode laser, traverses the

microscope optical chain, and is reflected back through the microscope, and

directed by a beam splitter onto a photodiode. In order to optimize thermal

map resolution, modulation frequencies upto a few MHz are used. A diagram of

the experimental setup is shown on the left. Reflectometry is a technique which relies on the local change of reflection

coefficient in a heated sample. In such, requirements on sample surface

finish place conditions on what pretreatment may be required. The technique

is more complex than direct IR radiometry in that in addition to a modulated

source it requires a probe beam, which is reflected off of the sample

surface. The relative change of the sample reflectance due to the

temperature change in the typical linear case is given by

Reflectometry is a technique which relies on the local change of reflection

coefficient in a heated sample. In such, requirements on sample surface

finish place conditions on what pretreatment may be required. The technique

is more complex than direct IR radiometry in that in addition to a modulated

source it requires a probe beam, which is reflected off of the sample

surface. The relative change of the sample reflectance due to the

temperature change in the typical linear case is given by